What Is Backfill in Construction? A Complete Guide

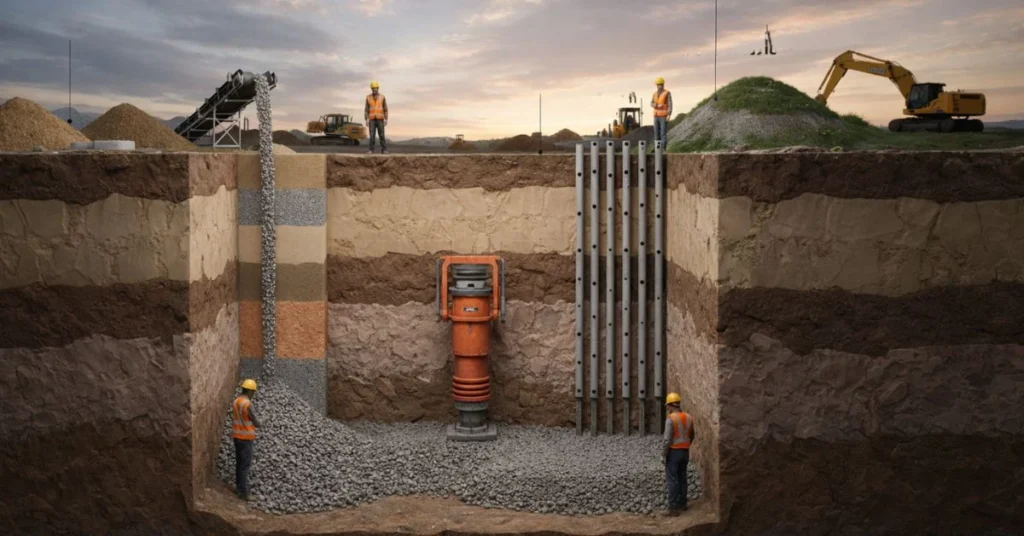

Construction involves numerous procedures and processes, and one of those is backfill. Firms need to understand that backfill in construction is the process of refilling an excavated area by returning soil and other materials after foundations are installed. Backfilling is important for the reason that it restores ground stability and supports the structures during construction.

Discovering this process also entails learning what is backfilling and its difference from filling. In construction, backfill and fill serve different purposes specifically, backfill is placed back into an excavation, whereas fill is added to raise ground levels. Hence, backfill is critical after excavation because it restores soil strength and protects any structures that are underground.

Backfilling is widely used in foundations, trenches, and retaining walls. This significant process helps engineers and construction workers maintain construction quality; thus, it’s essential to discuss backfill in construction. In this complete guide, there will be discussions of backfilling, its purpose, the step-by-step process, how it can be modernized, and more.

What Is Backfilling?

As mentioned above, backfilling in construction refers to placing soil and necessary materials into an excavated area after structural work is finished. The backfill meaning is a process that commonly occurs after installing footings, pipelines, and any other utilities.

With that, the backfill process in construction provides stability and protects structural materials. Once the process of excavation is finished, backfill is able to secure any underground cables and solidify the ground and the surface, which prevents issues like collapse.

What Is the Purpose of Backfill in Construction?

The purpose of backfill in construction revolves around how it can restore stability and strength post-excavation. Specifically, the importance of backfilling is paramount because of the following:

Structural Support for Foundations:

Backfill in construction reinforces how foundation walls are important and how there should be proper load transfer to the surrounding soil. Structural support prevents lateral pressure buildup, ensuring that there is consistent load transfer.

Preventing Settlement and Soil Movement:

With backfill, voids are reduced, and this prevents uneven settling as time passes. This also eliminates voids, which reduces the risk of surface depressions.

Improving Drainage around Structures:

The proper materials that are placed into the area help control water flow, resulting in less hydrostatic pressure. Improving drainage also prevents moisture-related damage and issues.

Protecting Underground Utilities:

Workers who backfill in construction are able to cushion the pipes and conduits from external stress, which protects any utilities that are underground. Protecting utilities also avoids shifting oil, vibration, and external loads.

Load Distribution and Safety Benefits:

By distributing load evenly through backfilling, compaction can improve overall structural safety and performance. Load distribution also enhances stability and job-site safety.

What Factors Affect Backfilling in Foundation Construction?

Foundation backfilling involves multiple factors, relating to technical and environmental aspects that can influence the structure’s long-term performance. Here are the factors to consider when choosing to backfill for foundation:

Soil Type and Bearing Capacity:

The specific type of soil that is used and its bearing capacity determine the suitable backfill in construction materials and required compaction levels. Soil type and bearing capacity can affect backfilling, as strong soils improve load support.

Moisture Content and Drainage Conditions:

In terms of moisture and drainage, this affects the compaction quality and long-term soil behavior. Moisture and drainage conditions must be managed to prevent erosion and future settlement issues.

Foundation Depth and Design:

Additionally, how deep the foundation is and its design also influence backfill selection and placement methods. Foundation depth and design affect backfilling in terms of stricter foundation methods and material selection.

Climate and Weather Impact:

The area’s common climate and weather are also factors to regard, as conditions like rainfall and temperature changes can affect the foundation backfill requirements. Climate and weather impact is a factor, considering how it can directly affect foundation backfill requirements.

Local Construction Codes and Standards:

Lastly, the local construction codes and standards during the stage of building stage must also be acknowledged. It ensures there is compliance, safety, and structural reliability across construction projects. Construction codes and standards influence backfilling with how compliance can ensure safety and can even avoid costly failures.

How to Choose the Right Backfill Material?

Other than the listed factors, it’s important for the engineers and construction workers to choose the right backfill material in construction. Using the best backfill soil for a specific area ensures stability and proper drainage; thus, choosing the most appropriate types of backfill material is highly fundamental.

Choose the best backfill soil by taking into account the following:

Characteristics of Good Backfill Material

When choosing a good backfill material, workers should consider:

- Backfill should compact easily.

- Backfill needs to provide adequate load support.

- Backfill must resist any excessive moisture retention

- Backfill has to maintain long-term stability.

Structural vs Non-structural Backfill

Purpose | Typical Use | |

Structural backfill | Supports loads and foundations | Foundations, retaining walls |

Non-structural backfill | Fills voids without load support | Landscaping, utility trenches |

Drainage Requirements

In terms of proper drainage, the requirements include:

- Prevents water buildup

- Reduces pressure on structures

- Minimizes settlement risks

Cost vs Performance Considerations

Low-Cost Materials | High-Performance Materials | |

Initial cost | Lower | High |

Long-term performance | Moderate | High |

Maintenance risk | Higher | Lower |

Why Is Backfill Compaction Important?

Learning more about backfill in construction gives a notion of its importance in the construction process. Particularly, backfill compaction is significant for multiple reasons, such as:

Effects of Poor Compaction:

Proper backfill compaction prevents settlement, cracking, surface deformation, and other maintenance risks.

Required Compaction Density:

The compaction density ensures that the backfill in construction is able to safely support the design load and installed structural elements.

Moisture Control during Compaction:

Where there is rain, there is moisture that can improve the soil bonding. This results in achieving consistent soil compaction for backfill.

Layer-by-Layer Compaction Process:

Having a gradual placement can allow uniform density, which reduces the risk of hidden voids after the compaction process.

What Is the Ideal Backfilling Period and Lift Thickness?

During construction, engineers and workers aim to have the optimal structure and building process. It starts with the ideal backfilling period and lift thickness.

The backfilling process in construction can be efficient with the following factors:

Timing of Backfilling after Concrete Curing:

Backfill in construction should only begin after the concrete has reached the4 sufficient strength.

Recommended Lift Thickness:

The recommended lift thickness in backfilling ranges from 150-300 millimeters to allow proper compaction.

Compaction between Layers:

Each lift must be compacted before adding another layer in order to control the backfill depth. Doing this prevents settlement and other issues.

Common Timing Mistakes to Avoid:

In certain pipeline installation projects, a common mistake in backfilling is doing it too early. This damages the structures and reduces load capacity.

What Materials Are Used for Backfill in Construction?

Backfill in construction involves replacing materials in an excavated area. The backfill materials can vary, and it’s imperative for engineers and construction workers to know the types of backfill in construction.

With the different applications, drainage and load requirements, and environmental considerations in mind, the construction project and its outcome can be more than sufficient when understanding the following materials used:

Coarse-Grained Soils for Backfilling

One material to use for backfill in construction is coarse-grained soil, which includes sand backfill and gravel backfill. These specific materials are widely used in backfilling, since their advantages can support stability while allowing water to pass freely underground.

Coarse-grained soil is best used for cases with residential housing developments wherein sand and gravel are placed around foundation and drainage systems to limit moisture buildup. Sand and gravel are appropriate for this particular case with their drainage performance, making them ideal for foundations and utility trenches.

Fine-Grained Soils with Low to Medium Plasticity

Another material is fine-grained soils with low to medium plasticity, like clay backfill with controlled soil plasticity. These soils are acceptable in construction when drainage demands are low and space constraints currently exist.

However, it’s also best to recognize risks like shrinkage and swelling in order to resolve the issues as soon as possible. Proper compaction techniques can be a solution correct moisture conditioning and layered compaction can support backfilling while minimizing any cracking.

Commercial and Industrial By-Products Used as Backfill

In addition, commercial and industrial by-products can also be used as backfill. These materials include fly ash backfill and recycled backfill materials, which are regarded as sustainable alternatives in modern construction. Not only does this material reduce landfill waste, but it can also support the need for an ideal building structure. Performance can vary for this particular alternative. Hence, it’s required to conduct a strength test and settlement analysis. Regulatory approvals are also crucial for this material as guidance when using it.

What Is Controlled Low-Strength Material (CLSM)?

CLSM backfill, encompassing flowable fill and controlled low-strength material, is a material that self-compacts a mixture of cement, water, and aggregates. Using CLSM backfill is advantageous in terms of simple placement, eliminating mechanical compaction, and reducing labor.

It’s best to apply and utilise CLSM backfill in municipal infrastructure projects where the material is frequently used for utility trench backfilling. The material reduces labor and future settlement, making it easy for time-sensitive construction work.

Why Use Compacted Stone for Backfilling?

Furthermore, compacted stone is also used for backfilling. Crushed stone backfill and compacted stone are able to provide high load-bearing capacity and excellent drainage. These materials are known for distributing loads evenly and resisting deformation. Compacted stone is commonly used beneath road bases and bridge approaches. It can handle repetitive loads, so compacted stone remains a reliable material solution for demanding backfilling projects.

When Is Lean Concrete Used as Backfill?

Lastly, the lean concrete is used when high strength and long-term durability are needed. Lean concrete backfill provides support when soil performance is uncertain.

Although costs are higher than other options, lean concrete backfill is most beneficial for its durability and load resistance. This specific material is utilised for projects like data center construction, which involves foundations and heavy equipment.

What Equipment Is Used for Backfilling in Construction?

When it comes to construction, the equipment used is highly impactful. Therefore, it’s necessary to choose the appropriate backfilling equipment for a project. Equipment selection depends on site size, access constraints, and material type.

Manual backfilling can be applied when space is limited, whereas machine backfilling is done for large projects that need loaders and excavators. Here are more backfill machinery and other construction backfill tools to use:

Excavators Used for Backfilling:

Excavators are used for precisely placing and distributing backfill in construction. This specific equipment is commonly used for foundation and trenches, as it can support controlled backfilling.

Loaders for Backfill Operations:

On the other hand, loaders are able to transport and place large volumes of backfill material efficiently. Loaders are constantly utilised for projects with open sites where speed and materials are needed.

Trenchers for Backfilling Work:

This specific equipment is most necessary for narrow, linear excavations and coordinated backfilling. Often paired with compaction tools, trenchers are built to maintain trench stability.

Compactors for Backfill Compaction:

Another equipment is compactors, which can densify soil layers to achieve the required strength for backfilling. Having proper compaction can define proper backfilling, avoiding any future settlements.

What Are the Common Backfilling Methods?

There are also common backfilling methods, and it’s significant for engineers to discover which backfill technique is necessary to use for a complex project. Considering method selection criteria and the advantages and limitations of each method, here are the common backfilling techniques used recently:

Compaction Method of Backfilling:

One method is when backfill material is placed in layers and is mechanically compacted. The compaction method is used by construction workers when planning to achieve the required density, ensuring stability and minimizing settlement. It is best used for foundations, road subgrades, and other projects where settlement control is critical.

Water Jetting Method:

To add, the water jetting involved using water to settle granular backfill around structures and utilities. Although it requires thorough drainage control, water jetting is a method suitable for clean sands. The water jetting method is most appropriate for utility trenches, pipe bedding, and areas with clean sand.

Filling Method:

Filling refers to how backfill material is placed without intensive compaction. This method is best for projects in non-structural areas where load demands are minimal. Particularly, the filling method is necessary for landscaping areas, temporary fills, or non-structural zones with low load requirements.

Dumping Method:

The last method to use is dumping, in which materials are dumped directly into the excavation with limited control. The dumping method is used in temporary and low-risk backfilling construction projects. With that, this method is highly suggested for projects with temporary works, emergency fills, and low-risk areas.

What Is the Step-by-Step Backfilling Process in Construction?

Like any other process in construction, backfilling has steps. The backfill procedure helps engineers and construction workers learn how to backfill from site inspection and preparation, material placement, layered compaction, to final grading and finishing. Here’s the step-by-step backfilling process:

1. Scheduling and Preparation for Backfilling:

In this first step, backfilling is scheduled for an easy project start – beginning at the right time and under the proper conditions. Scheduling and preparation for backfilling involves confirming that concrete curing, waterproofing, and utility inspections are finished before any building and construction starts.

2. Execution of Backfilling Work:

After the first step, it’s crucial to follow the correct execution of backfilling work. The second step of the backfilling process places and compacts the necessary materials according to the design requirements. As a result, soil and other aggregates are in controlled layers.

3. Final Surface Finishing and Inspection:

The last step of the backfilling process is the finishing and inspection, which ensures that the completed backfill is performing best. Final surface finishing and inspection involve correct grading, drainage, and surface stability. It also verifies compliance while validating the quality and safety of the backfill.

How Is Technology Improving Backfilling in Construction?

Modern construction brings the idea of improving backfilling and construction with technology. Specifically, drone technology in construction indicates how site surveys can be conducted easily, safely, and even faster when using drones. Construction technology utilizes drones, as it is engineered to create accurate, up-to-date data that can expedite the backfilling process.

Drones and unmanned aerial vehicles (UAVs) can also help firms with volume calculation for backfill. The advanced technology is built to deliver the correct quantity of the chosen materials, which can reduce waste and cost overruns. Aerial analytics showcases drone data to calculate with greater precision in comparison to manual estimates.

Additionally, construction technology can also help with progress monitoring and documentation. Drones offer clear visibility of backfilling and can provide transparent records of the construction. By utilizing this innovation, accountability can be maintained as well as consistency for the construction project.

There is also the matter of accuracy and cost-effectiveness, in which drones improve accuracy and can save overall project costs. Drone technology in construction minimizes rework by identifying errors in advance through aerial analytics. Consequently, fewer corrections imply lower labor and fewer material expenses.

How Do Drones Improve Backfilling Accuracy in Construction?

Adding to drone technology improvements, backfill in construction can also be developed with drones and UAVs. Drones in construction can expedite the backfilling process through the following:

Site Surveying and Volume Measurement:

Equipped with advanced tools, drones utilised in site surveying and volume measurement can help engineers establish accurate ground conditions. Drones offer precise volume measurement, which helps in avoiding material shortages and overfilling. Drones in construction can be used for aerial surveying to generate detailed elevation 2D and 3D models, and can even calculate volumes efficiently.

Monitoring Backfilling Progress:

Utilising drones also helps engineers by monitoring the backfilling process. Progress monitoring is done better with drones, as it can confirm that the backfilling has followed the approved designs and schedules. Drones in construction can visually track all stages of the backfilling process, resulting in helping engineers identify any errors like uneven layers and missed areas. Consistent monitoring through drones leads to quality control and verifiable construction activity.

Improving Safety During Backfilling:

Most importantly, drones can also improve safety during backfilling. Deploying drones reduces the need for workers to enter unstable or confined areas or have workers to be in near proximity to hazardous situations. Since drones in construction provide overhead visibility of the site, there is a lack of direct exposure to moving equipment. Consequently, engineers and construction workers are safe within a distance while maintaining accuracy throughout the project.

Using ZenaDrone for Backfill Planning and Inspection:

ZenaDrone offers advanced technology that supports data-driven planning and inspection throughout the backfilling process. Drones in construction with aerial surveying for backfill is an optimal combination, considering it provides reliable insights to construction teams for a smoother workflow. With that, ZenaDrone aims to support backfill planning and inspection by providing drones and UAVs that can help with decision-making.

Cost and Time Savings with Drone Technology:

Drones are also able to reduce cost and time. This helps with aerial surveying for backfill as it minimizes rework by identifying any problems early. Data gathered by drones is able to help contractors in avoiding repeated material hauling. As a result, projects are up to schedule and are maintained within the project’s budget.

What Are the Best Tips for Backfilling a Foundation?

After understanding how backfilling works, it’s imperative to take into consideration foundation backfilling tips. Engineers and construction workers have to acknowledge how the backfilling process can be greatly influenced by backfilling best practices, such as:

Avoiding Over-Compaction:

In order to avoid over-compaction, construction workers opt to only transfer the necessary lateral pressure onto foundation walls. Maintaining structural integrity and following adequate soil support around the foundation prevents excessive compaction. This results in balanced density with flexibility.

Ensuring Proper Drainage:

Water accumulation is one of the leading causes of foundation failure. With that in mind, engineers have to ensure that there is proper drainage, wherein systems are properly assessed and established. Correct drainage management leads to less hydrostatic pressure, leaks, and material degradation.

Preventing Foundation Damage:

Another foundation backfilling tip is to prevent foundation damage, which involves the right sequencing, suitable materials, and even placements. This tip is best applied during the early construction stage. Preventing foundation damage requires coordination and engineering guidance, resulting in long-term performance.

Quality Control Checks:

Most importantly, checking the quality control is essential. Quality control checks are able to verify that the backfilling meets the standard design, safety, and performance. Incorporating quality control into foundation backfilling leads to accountability and consistency in the construction project.

How Much Does Backfilling Cost in Construction Projects?

Cost is an important matter and value to firms, whether for construction or for other industries. The construction industry has to consider numerous costs, including the backfilling cost. Backfill pricing covers multiple aspects of construction, including:

Cost per Cubic Meter/Yard:

Learning the cost per cubic meter or yard impacts the project budget, as pricing is typically calculated by volume. This indicates that costs vary based on the material type, site access, and compaction requirements. With that, the cost may range from relatively low-cost granular fill to higher-cost engineered materials.

Labor and Equipment Costs:

Another cost to consider is the labor and equipment costs, which include translating backfilling plans into execution realities. Construction regularly will need to hire skilled operators, laborers, and will even need the appropriate machinery like excavators, loaders, and compactors. This results in evaluating the selected labor and desired equipment.

Material Cost Comparison:

Other than those mentioned above, material cost must also be compared in order to balance performance requirements, even with budget constraints. Engineers have to be particular when selecting the appropriate material, which plays a vital role in both structural outcomes and backfilling cost.

Factors affecting Total Cost:

Overall, the factors that affect the total cost must be identified. Engineers are able to have a realistic view of the total backfilling cost beyond basic estimates, making it easier to decipher which factors cost the most. Total cost is the sum of many interconnected variables, and learning which those are can help the construction project be cost-effective.

FAQ’s About Backfill in Construction

What is the difference between backfill and fill-in construction?

Backfill in construction is the process of material being placed back into an excavated area, whereas fill is the process used to raise ground levels.

What are the main purposes of backfill in construction?

The main purpose of backfill in construction is to provide structural support, to prevent settlement, to improve drainage, and to protect all underground utilities after excavation activities are finished.

Which materials are best for backfilling a foundation?

The best materials for backfilling include sand, gravel, crushed stone, or engineered fill, selected based on drainage, load requirements, and foundation design.

How is backfill compacted properly in construction projects?

Backfill is compacted properly through layers using mechanical compactors, with moisture control that can achieve the required density and long-term stability.

Can drones be used to improve backfilling accuracy?

Yes. Drones are able to support backfill by improving volume measurement, progress tracking, and quality control through accurate aerial data.

How do you calculate the quantity of backfill needed for a site?

To calculate the quantity of backfill needed for a site, subtract volumes from excavation, which is often enhanced by drone surveys for greater accuracy.

Contact Us

Thank you for your message. It has been sent.