What is AHRS and How Does It Work? Complete Guide

AHRS system stands for Attitude and Heading Reference System, and it’s particularly used as a navigation reference system that determines an object’s current orientation in three-dimensional space. This system is created to provide precise 3D orientation data, measuring the roll, pitch, and yaw. Having accurate orientation tracking verifies the relevance of an AHRS over older mechanical instruments.

With features that are compact, digital, and more reliable, AHRS indeed matters in modern navigation. Technology-driven demands bring the need for a modern navigation reference system, enhancing user experience in terms of safety, accuracy, and system resilience. Hence, the AHRS system becomes increasingly central in modern navigation, along with digital navigation platforms.

As a result, it’s vital to adopt the attitude and heading reference system in this digital era. This system puts most, if not all, industries at an advantage, including the construction equipment industry, the robotics industry, and aviation, amongst others. In this complete guide, discover more of what AHRS can do through comprehensive discussions of how AHRS works, what its benefits are, and more.

How Does an AHRS System Work?

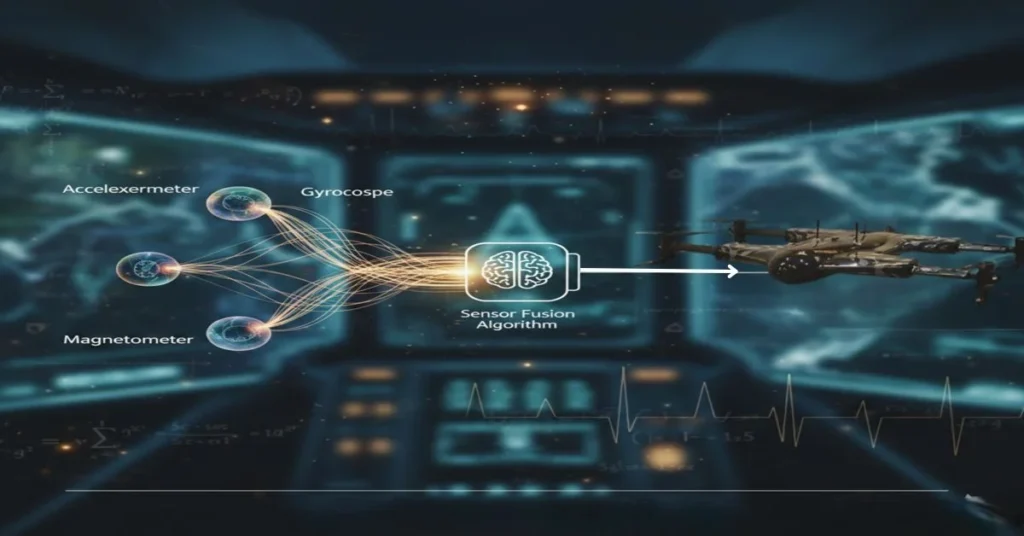

Learning how AHRS works reduces uncertainty with navigation reference systems, and it starts by understanding the internal architecture of an AHRS system. The AHRS system is able to work through a sensor-fusion-based navigation reference system that is designed to precisely track the orientation of an object. AHRS architecture is capable of such accuracy by redundancy, making the orientation still reliable despite potential issues like rapid motion and signal loss.

In addition to its internal architecture, there is also the AHRS workflow from sensing to outputs. Beginning with raw sensor data collection, where the data will be gathered, and then processed through the AHRS architecture, a sensor fusion algorithm that works to become a unified orientation model. Consequently, the workflow is improved in terms of clear, real-time orientation data.

Moreover, the attitude and heading reference system works on numerous AHRS working principles. In fact, AHRS is capable of functioning through multiple sensors, sensor fusion, and 3D orientation. These are all feasible, most especially now in modern industries where complex projects require the best and foremost technology.

What Sensors Are Used Inside an AHRS?

Learning the types of sensors used inside an AHRS helps in identifying which are most helpful for a particular case or mission. It’s crucial to understand why each sensor is needed and how all AHRS sensors can work together to bring balance to the navigation reference system. More specifically, modern AHRS sensors, also known as IMU sensors, are as follows:

- Gyroscopes: A sensor for measuring angular velocity and detecting rotational movement is classified as Gyroscopes. This particular sensor is used for real-time orientation tracking in an AHRS system, making it essential for short-term accuracy and changes to smooth attitude. Specifically, aerospace utilizes gyroscopes in aircraft AHRS systems in order to ensure a stable flight attitude during turbulence.

Strengths | Limitations |

Very responsive, excellent for detecting rapid motion, and critical for attitude stabilization. | Prone to drift over time, which can cause heading errors if not corrected by other sensors. |

- Accelerometers: Used in measuring linear acceleration and gravity, Accelerometers are capable of determining the pitch and the roll within an AHRS system. This specific sensor is built to provide a stable reference for leveling. With that, marine navigation uses accelerometers in ship AHRS systems to help maintain vessel balance while detecting tilting in rough seas.

Strengths | Limitations |

Reliable for long-term orientation, simple, and energy efficient. | Sensitive to vibration and sudden movements, which can reduce accuracy in dynamic conditions. |

- Magnetometers: Lastly, magnetometers are needed to measure the Earth’s magnetic field and to provide an absolute heading reference for the AHRS system. This exact sensor can correct long-term drift from gyroscopes. For autonomous vehicles, magnetometers are essential for guiding orientation when GPS signals are weak and blocked.

Strengths | Limitations |

Accurate heading data and long-term stability. | Affected by magnetic interference from metal structures and electronic equipment. |

How Sensor Fusion Enhances AHRS Accuracy?

Furthermore, the navigation reference system’s accuracy can be augmented by an AHRS sensor fusion, which refers to the foundation that allows an AHRS system to deliver reliable orientation data. Sensor fusion can particularly help in real-world conditions by blending data from the sensors (gyroscopes, accelerometers, and magnetometers), resulting in the system maintaining accurate orientation tracking. The purpose of sensor fusion is to fulfill that, proving that an AHRS sensor fusion is essential for the navigation reference system to be optimal.

More on AHRS sensor fusion is its Kalman filter, a mathematical process that continuously predicts motion using gyroscope data. This then corrects that prediction using accelerometer and magnetometer measurements, essentially making the Kalman filter a process that corrects any errors. With that, the Kalman filter process can enhance AHRS accuracy by making decisions based on confidence and environmental conditions.

The real-time noise reduction is also another key benefit. Realistic cases that involve relying on AHRS to maintain heading in extreme conditions, and noise reduction is filtered out by an AHRS sensor fusion, preserving reliable orientation data. Not only is there less disturbance, but workers are also able to obtain better situational awareness.

How Does AHRS Output 3D Orientation?

3D orientation refers to the angular position and direction of an object in three-dimensional space, and in this case, AHRS is able to output 3D orientation by converting sensor data into clear orientation outputs such as yaw, pitch, and roll. This provides a reliable navigation reference system that is most efficient in operational environments.

Orientation calculation begins with AHRS sensor fusion inside the system, involving the gyroscopes, accelerometers, and magnetometers. The mentioned sensors are intended to be mathematically combined, with the output being a computation of an object’s spatial orientation. Calculations are converted into Euler angles in consideration for human readability and system compatibility, which ensures accuracy and usability across platforms in comparison to quaternions.

With different industries, there are different data formats to rely on. For the industrial robotics manufacturing industry, AHRS orientation output is essential for maintaining precise alignment. Quaternions are chosen for cases that involve motion control, whereas Euler angles are needed for situations that require monitoring and calibration; thus, it’s significant to learn what data format the project and industry depend on in order to ensure both machine precision and human understanding.

Where Is AHRS Used?

As mentioned above, AHRS is consistently utilised by multiple industries. AHRS applications lead these organizations to a point where technology creates real operational value. Here are industry-wise applications, including AHRS in aviation and AHRS for drones:

- Aviation: Flying and operating aircraft can be improved with AHRS, replacing traditional mechanical gyros with digital reliability. The system provides the skilled pilots with continuous attitude and heading data, which can be most beneficial in highly critical missions. It also supports glass cockpit displays, enhancing the situational awareness and flight safety of the pilots.

- Drones & UAVs: Modern drones and Unmanned Aerial Vehicles (UAVs) are able to benefit from an AHRS in terms of UAV stabilization and precise maneuvering. Specifically, survey drones rely on AHRS to maintain level flight while still navigating autonomously to obtain consistent data.

- Marine: Military personnel trained for sea and land operations will perform better with AHRS, as it helps vessels maintain heading in rough seas. Real cases with commercial shipping operators have used AHRS to stabilize onboard navigation systems, thus improving the accuracy of the ship’s route.

- Robotics: Additionally, industrial robots depend on using AHRS for a better understanding of spatial orientation. Electronics manufacturing has utilised AHRS feedback for robotics arms, aligning the components accurately while reducing the defects and the downtime.

- Defense: With defense platforms, AHRS is utilized for guidance and stabilization in land and aerial systems. Unmanned ground vehicles depend on AHRS’s capability to help them navigate rough terrain and uncertain surroundings.

- Autonomous Vehicles: The last industry-wise application is for autonomous vehicles, where AHRS is integrated in sensors stack for real-time orientation awareness. Having integrated AHRS ensures safe lane positioning and smooth motion control, which completes the broad landscape and can use the foundational value of the AHRS system.

How Does Zenadrone 1000 Use AHRS Technology?

After knowing how AHRS can improve numerous industries’ methods and workflows, it’s essential to learn how ZenaDrone 1000 stays ahead by using AHRS technology. It’s inadequate to just learn what is AHRS; it’s paramount to also discover how ZenaDrone 1000 integrates an advanced drone AHRS system for reliable orientation tracking. The integration of ZenaDrone 1000 AHRS starts with flight control architecture, where sensor fusion feeds the UAV orientation system in real time.

Consequently, the aircraft can continuously understand the pitch, roll, and yaw. Having this consistent attitude update, the drone is now capable of active stabilization technology. Flight control is also better with the active correction for wind gusts and load shifts, making flight operations more efficient.

To add, AHRS supports precise navigation and autonomous flight. Aligning the orientation data with mission planning software allows the drone to follow predefined routes more accurately. With this advancement, operators intervene less during missions while still preserving the drone’s data quality.

Having ZenaDrone 1000 AHRS guarantees reliability on orientation tracking, flight endurance, and mission repeatability. Compared to standard commercial drones that heavily depend on the Global Positioning System (GPS) alone, the ZenaDrone 1000 AHRS is at an operational advantage, especially in industrial UAV platforms.

What Are the Benefits of Using an AHRS?

By now, it’s well established how AHRS systems can be beneficial for a lot of industries. There have been brief mentions of the AHRS benefits, including technology-driven and AHRS accuracy. Here are some of the many AHRS benefits:

- High precision: One of the key benefits of utilising AHRS is the precision that it offers across multiple axes. The system is able to maintain multi-axis stability by continuously calculating the pitch, roll, and yaw as intended. AHRS accuracy allows this precision, reinforcing how an attitude and heading reference system is still trusted where margins for error are small. Aviation can benefit most as they need high precision for safe flight, involving the pilots with clearer situation awareness offered by AHRS systems.

- Reliability: Another benefit of using AHRS is its reliability, which is achieved through redundancy and sensor fusion. The AHRS system is capable of delivering usable data, resulting in operations remaining predictable and resilient. Workers have the peace of mind with this system in consideration. The maritime industry can have one of the most demanding missions, and the reliability provided by AHRS systems will help them in maintaining heading during rough seas.

- Cost-Effective Replacement of Older Systems: In comparison to mechanical gyros or other navigation systems, AHRS is regarded as a cost-effective alternative. Having fewer parts of systems brings an opportunity where there are fewer expenses to cover, and operators find it easy to replace older systems with digital AHRS units. Maintenance cost is reduced while improving situational awareness through an AHRS. Rail transportation can use the AHRS systems, considering how it can replace aging inertial systems.

- Suitable for Multiple Industries: The adaptability of AHRS benefits numerous industries, as mentioned above. With AHRS, industries can benefit in terms of precision, reliability, and value, especially in cases where accurate orientation tracking is vital. Robotics and automation is flexible, with multiple and complex projects that can be fully supported with the dynamic support offered by AHRS systems.

How Do You Choose the Right AHRS System?

Once understanding how AHRS works and how it can benefit multiple industries, it’s important to choose an AHRS system. There are AHRS specifications to consider, and it’s better to decipher the AHRS comparison. When choosing the right AHRS system, bear in mind the following:

- Performance Specifications: Reviewing AHRS specifications involves confirming the performance specifications like accuracy, update, rate, and drift, especially under real operating conditions. AHRS comparison highlights the angular accuracy and sensor stability, which directly support data quality. Hence, performance metrics must be highly regarded so that it aligns with how the AHRS system will be used.

- Size, Weight, Power: Another requirement to consider is the Size, Weight, Power (SWaP), including the limited payload or energy. Choosing an AHRS system with the appropriate SWaP characteristics gives better performance and smooth integration while maintaining reliable orientation tracking.

- Testing in Real Environments: Other than datasheets, the AHRS system must also be tested in real environments. This testing validates the performance under different conditions like vibration, temperature changes, and even electromagnetic interference. Conducting this test in real environments confirms that the chosen navigation reference system is capable of performing consistently despite unavoidable circumstances.

- Errors to Avoid: Most importantly, avoid common mistakes like overlooking certification needs and selecting AHRS systems based solely on their price. There must be a careful evaluation of numerous factors, such as matching specification, SWaP, and real-world validation.

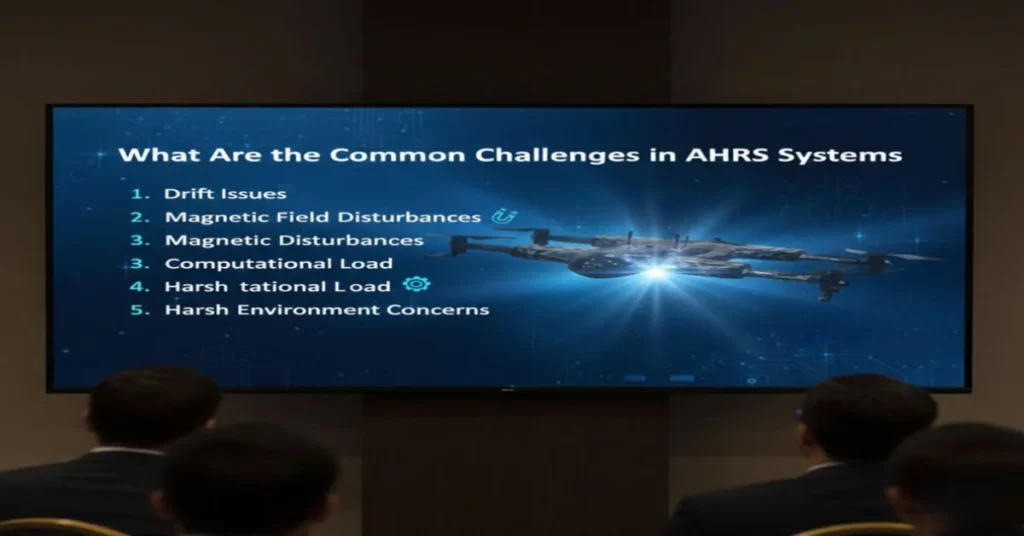

What Are the Common Challenges in AHRS Systems?

Although AHRS systems have proven their development and their impact on industries’ technologies, there are still problems and issues to face. The AHRS challenges vary depending on the use of the navigation reference system, from magnetic interference to sensor drift. These are the common challenges in AHRS systems:

- Drift Issues: One of the most persistent AHRS challenges is sensor drift, which is particularly from gyroscopes. This involves small measurement errors that are accumulated over time, which causes a gradual misalignment in attitude estimates. Resolving drift issues can help preserve long-duration accuracy, resulting in regular calibration for the gyroscope.

- Magnetic Field Disturbances: Additionally, magnetic field disturbances are also another common obstacle in which the magnetometers are affected by nearby metal structures or electrical currents. This impacts the heading accuracy, so it’s crucial to understand and plan in advance for shielding or adaptive algorithms.

- Computational Load: The AHRS system consistently processes data from multiple sensors in real time. Managing computation load properly ensures timely, stable outputs. By managing the load efficiently, system designers can balance algorithm complexity with available computing resources.

- Harsh Environment Concerns: Environmental noise, vibration, and temperature extremes will challenge the sensors’ ability to function. Not only is it unavoidable and unpredictable, but it can also be detrimental when it strongly impacts any of the sensors.

Hence, understanding AHRS challenges ensures informed selection, integration, and long-term reliability of navigation reference systems.

What Is the Difference Between AHRS and IMU?

While AHRS is used for orientation tracking, the inertial measurement unit (IMU) is designed to measure raw motion data. Although these two technologies support motion awareness, there are still differences between AHRS and IMU. These differences can directly affect the operational decisions for any upcoming projects.

Observe the table below to learn the difference between AHRS vs IMU, particularly the core purpose, sensor set differences, AHRS computing advantage, and the accuracy comparisons:

AHRS | IMU | |

Core purpose | Provides complete orientation tracking | Measures raw motion data only |

Sensor set differences | Gyroscopes, accelerometers, magnetometers | Gyroscopes and accelerometers |

AHRS computing advantage | Advanced onboard computation fuses sensors into stable orientation data | No internal processing or decision logic |

Accuracy comparison | Higher due to continuous error correction | Lower without additional processing |

How Much Does an AHRS System Cost?

After knowing more about AHRS systems and what they can do for many industries, the matter of AHRS cost is significant. It’s not a single sensor, but a complete navigation reference system designed for accurate orientation tracking. Therefore, pricing depends on the capability, reliability, and intended use.

- Pricing Tiers: The AHRS price range typically falls into three ranges, and it is as follows:

- Entry-Level AHRS Units: Frequently used in industries involving consumer robotics or basic stabilization tasks. These entry-level AHRS units are priced for their low price and affordability, yet keep in mind that these units only offer limited redundancy and accuracy

- Mid-Range Systems: These support industrial marine, or UAV applications, which balance sensor quality and onboard processing.

- High-End Systems: For this, it’s best for those who need compliance with aviation standards. The upper AHRS price range is often associated with industries like aviation, where AHRS costs include many factors like certification, redundancy, and rigorous testing.

- Factors Influencing Cost

Several factors influence cost, which explains the differences in AHRS system prices. Regardless of industry, cost is still influenced by factors such as:

- Sensor Grade: With higher-grade gyroscopes, accelerometers, and magnetometers, accuracy can improve, but the costs increase. This leads to better orientation tracking and lower drift; however, the issue of manufacturing and calibration costs is still pertinent.

- Onboard Computing Power: Another factor is the processing capability, considering that advanced onboard computing can perform real-time sensor fusion, error correction, and filtering without heavy dependence on external processors. However, this added intelligence raises system cost.

- Sensor fusion algorithms: Tighter error tolerances require more sophisticated calibration. There are applications where there is a high demand for a small error margin,s which leaves to needing precises components, extended testing, and stricter quality control.

- Environmental Tolerance: Other than that, environmental durability influences the price. As systems are designed to operate under vibration, temperature extremes, and electromagnetic interference, ruggedized hardware is needed.

- Certification Requirements: Finally, long-term support and lifecycle value, which includes firmware updates, integration support, and reliability over years of operation.

What Impacts Long-Term Value? More than the initial price is what impacts the AHRS system’s long-term value, indicating that the reliability is able to reduce recalibration time, minimize downtime, and improve safety across operations. Investing in the lifecycle savings and AHRS system justifies the higher costs.

How Often Should AHRS Be Calibrated?

Furthermore, AHRS calibration is crucial when using any navigation reference system. This process involves retaining accuracy over time across operating conditions. With that, the calibration frequency starts with identifying the schedules.

Standard calibration schedules vary, as they depend on the application and the current environment. There are cases that are based in controlled settings, like indoor robotics labs, where AHRS calibration may be required during initial installation or after hardware changes. Otherwise, mobile or outdoor systems regularly follow stricter calibration frequency and maintenance guidelines. Having this schedule, strict or not, ensures that the headings and attitudes are still consistent even with vibration, temperature changes, and prolonged use.

It’s best to take it a step further by recognizing the signs that an AHRS recalibration is needed. There are common indicators of such, including gradual heading drift, inconsistent roll or pitch readings, slow response to motion changes, or discrepancies between AHRS data and external references. By familiarizing oneself with these signs, operations are able to act faster and resolve issues immediately.

Overall, following the best practices can help maintain accuracy retention over the AHRS system’s lifespan. Doing good practices include calibrating in magnetically clean environments, following manufacturer procedures, logging calibration events, and rechecking calibration after firmware updates and hardware modifications. These actions may seem small, but identifying early warning signs can help in the long run by reducing downtime and operational risk.

Can AHRS Work Without GPS?

As mentioned above, using GPS alone is insufficient. Nonetheless, the attitude and heading reference system is fundamentally designed for real-time orientation tracking, which makes it function independently even without GPS. Unlike GPS, the AHRS system purely focuses on the attitude (roll, pitch, and yaw) by using onboard sensors.

AHRS without GPS is able to function independently because of its reliance on inertial sensors such as gyroscopes, accelerometers, and magnetometers. With these sensors, the AHRS can continuously measure rotational motion and linear acceleration, enabling orientation tracking through dead reckoning. AHRS does not require external signals like GPSS to determine attitude since the system works by utilizing the mentioned sensors.

In spite of that, there are still limitations of GPS-independent operations. Although the AHRS excels at short-term orientation tracking, the inertial sensors accumulate small errors as time passes, which can lead to drift. Without external references such as GPS, these errors cannot be corrected indefinitely and can cause constraints to the operations.

For cases that involve military and indoor use, AHRS systems are heavily utilised. Indoor simulators rely on AHRS systems for orientation tracking without emitting signals that could be detected, and the same is applied for indoor logistics robots, where large warehouses can use AHRS to navigate the aisles since GPS is unavailable. These real circumstances emphasize how AHRS can function without GPS, and why it is not only feasible but also essential.

FAQs About AHRS systems

What is AHRS used for in aviation?

Aviation uses AHRS systems to provide real-time attitude and heading information, which can support safe flight control, navigation awareness, and pilot situational understanding.

How accurate is an AHRS system?

The accuracy of an AHRS system depends on the sensor quality and calibration. Modern AHRS systems deliver highly reliable orientation tracking that is suitable for cases like professional aviation and UAV use.

What sensors does an AHRS include?

The AHRS includes combined sensors such as gyroscopes, accelerometers, and magnetometers that function together as a complete navigation reference system.

Why do drones use AHRS systems?

Drones use AHRS systems for stable flight, precise maneuvering, and autonomous navigation, especially in situations where GPS data is limited or unavailable.

How often should AHRS be calibrated?

Calibration schedules vary, but most AHRS systems require periodic recalibration during maintenance or when accuracy degradation is detected.

What is the typical cost of an AHRS system?

AHRS cost ranges widely, from affordable commercial units to higher-priced, certified systems used in aviation and defense applications.

Contact Us

Thank you for your message. It has been sent.